Problem Solving is an Art

It’s this revelation that has recently led our leadership team to fundamentally change the way we look at problems. Not only the way we address them, but more importantly, the way we view them and even the way we talk about them.

We now pour our energy and focus into becoming exceptionally good at the Art of Problem Solving. As a management team, we have committed ourselves to becoming highly specialized and skilled problem solvers in each of our areas of responsibility.

I’m trusting that as you journey with us, you’ll enjoy seeing all the fruits of our exceptional problem-solving team’s labours as much as we’re enjoying implementing them! Regards,

Bronwynn Dreijer

RAW STORES

Our Raw Stores have recently been upgraded to include a live central feeding system allowing us to better manage our raw materials & storing the stock per type in batches.

IMM PLANTS

We have moved our first four injection moulding machines into IMM Plant 3. They are now operational and running.

TOOLROOM

Our Toolroom gantry has been installed. This will ensure a safer working environment for our staff and assets, whilst allowing for improved efficiency.

ASSEMBLY

We have added a mezzanine floor to our assembly plant providing for a dedicated small components assembly area. The area below the mezzanine has been allocated as a dedicated assembly components store which will improve both assembly processes and traceability.

DISTRIBUTION

We are in the process of updating our vehicle branding so that our fleet is easily identifiable when making deliveries. Our highly capable drivers are sent for appropriate training to ensure products are well cared for whilst in transit.

D & E

We have shifted our D&E team onto Fusion 360 which is a fully-connected product development system. It specializes in 3D CAD, CAM, and CAE. The team is enjoying its advanced capabilities.

SYSTEMS

We have relaunched our ERP manufacturing module which now allows us to efficiently and accurately track product movement across our plants via a barcoding and scanning system.

QUALITY

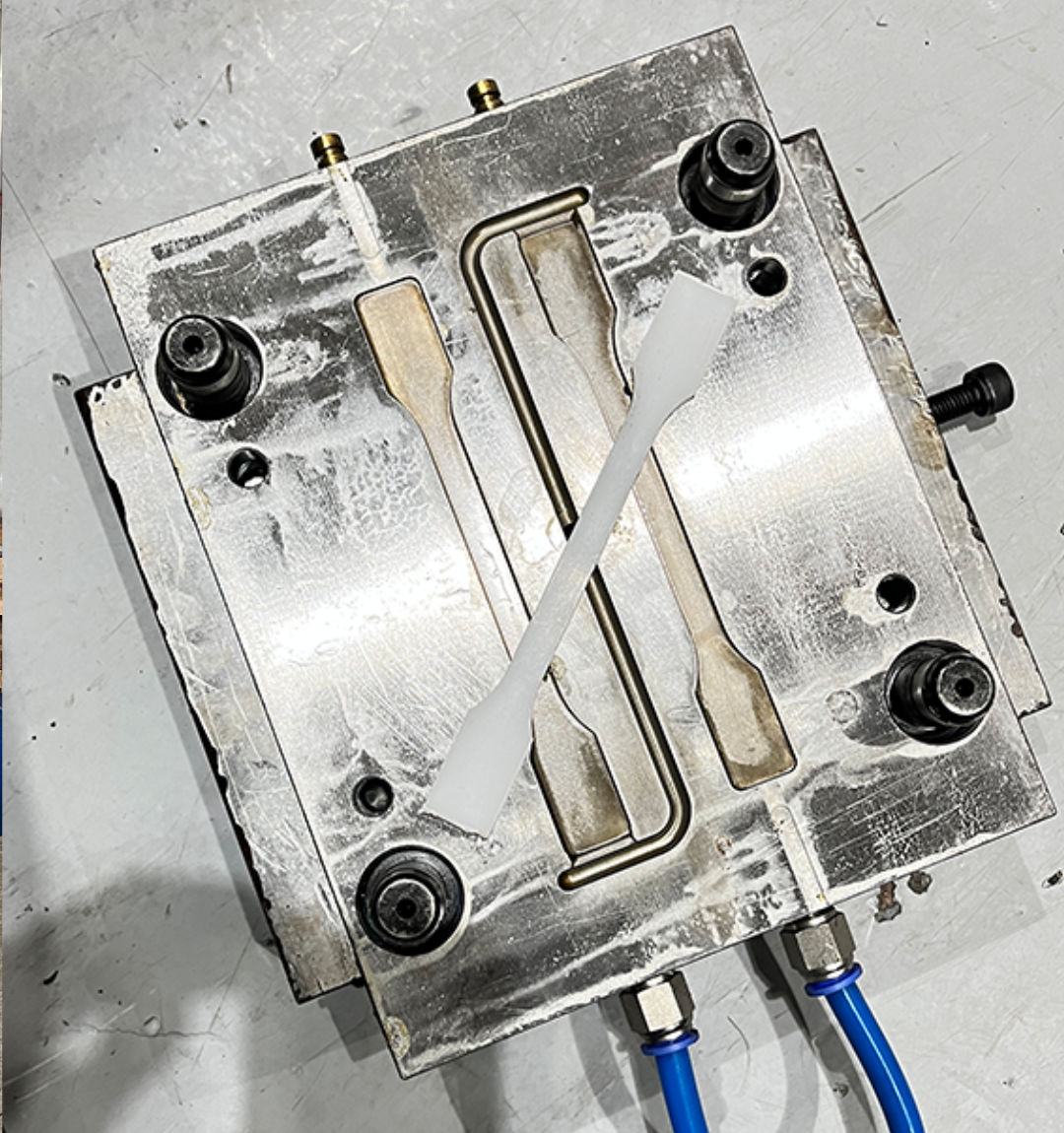

We have developed a dogbone mould which enables us to make samples of material received, so that we can test tensile and compression strength. This allows us to determine whether the material strength is in accordance with the required specifications.

CULTURE

Our management team attended the King Price Culture Tour & we have drawn great inspiration from them & are implementing some of their amazing key principles into our business.