+27 (11) 708 4755

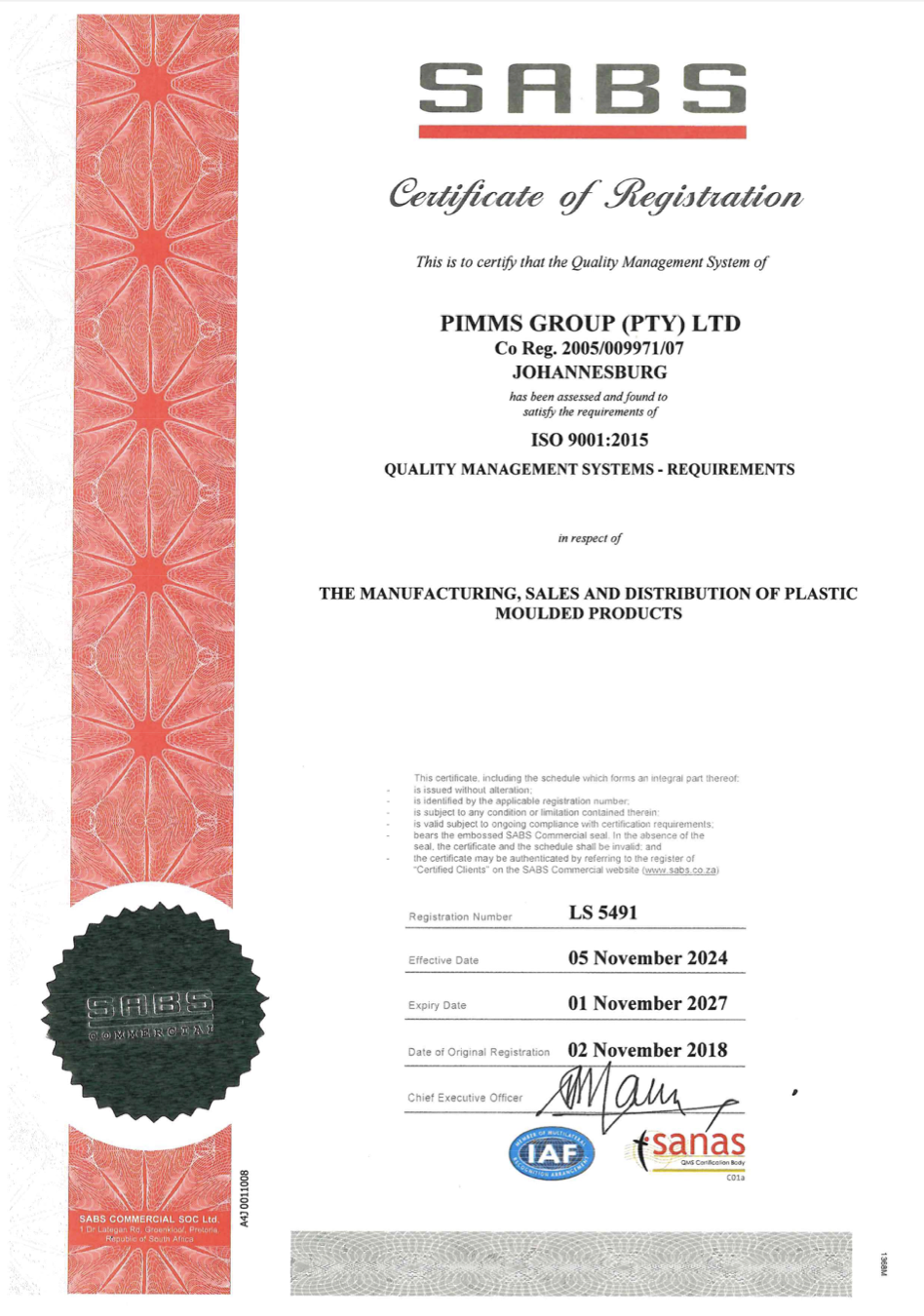

At PIMMS Group, we provide end-to-end injection moulding solutions, from tool manufacturing to high-precision production and assembly. Whether you need multi-shot moulding, cleanroom production for pharmaceuticals and cosmetics, or expert tool management, we deliver quality, efficiency, and reliability. With ISO 9001:2015 certification and a strong focus on custom-moulding, we ensure that every component meets your exact specifications.

Explore our services below to see how we can support your manufacturing needs

Great products start with great design. While PIMMS Group specializes in precision injection moulding, Stanton Global helps bring ideas to life with expert design and engineering. From concept to prototype, they ensure your product is optimized for manufacturing, efficiency, and performance.

Stanton Global can assist with

Concept Development & Feasibility Analysis

Product Design & Prototyping

Engineering for Manufacturability

Design Testing & Optimization

Seamless collaboration from design to production ensures a smooth,

high-quality manufacturing process

PIMMS Group offers comprehensive toolroom services to ensure your tools are manufactured, maintained, and managed with precision and care. From custom tool manufacturing to long-term maintenance and storage, we provide reliable solutions to keep your production running smoothly.

Our toolroom services include

Tool Manufacturing

Project Management of Tools From Other Countries

Tool Maintenance & Repair

Tool storage

We ensure your tools are in optimal condition, helping us maintain efficiency and reduce downtime

We support the industrialisation phase of your product by selecting and testing the right materials for optimal performance and manufacturability. Our focus is on ensuring that every component meets your exact requirements while optimising the production process for efficiency and cost-effectiveness.

Our industrialisation and material selection services include

PLASTIC SELECTION AND TESTING

Identifying the best materials for durability, functionality, and cost-efficiency, followed by rigorous testing.

OPTIMISATION FOR MANUFACTURING EFFICIENCY

Fine-tuning designs and materials to streamline production processes and reduce costs.

ENSURING COMPLIANCE WITH INDUSTRY STANDARD

Adhering to all relevant quality and safety standards, ensuring your products meet regulatory requirements.

We work closely with you to guarantee that the chosen materials and processes

deliver the best results for your project

At PIMMS Group, we offer advanced injection moulding solutions to produce high-quality, precision plastic parts across small, medium, and large-format components.

With injection moulding machines ranging up to 4,500 tons, our expertise spans various techniques to meet diverse industry needs, ensuring efficiency and reliability in every project.

Our injection moulding capabilities include

Multi-shot moulding

Insert moulding

Gas-assisted moulding

Cleanroom moulding for pharmaceutical & cosmetic industries

Multi-part assembly

We deliver custom solutions, from complex components to fully assembled products,

with a focus on quality and performance

Our clean room facility is designed for the production of pharmaceutical and cosmetic-grade plastic packaging in a controlled, low-contamination environment. We follow core clean room principles to maintain high levels of hygiene and product integrity.

Our Clean Room Manufacturing includes

Controlled environment for pharmaceutical and cosmetic packaging

Operates according to clean room best practices

Designed to minimise contamination

and reduce reworks

Supports consistent product quality

and repeatable results

Enables proactive quality control, a top priority for our pharma clients

The Clean Room Advantage

Running a clean facility fosters a strong quality culture. Our team becomes conditioned to high standards, and this mindset continues across departments. It’s an investment in quality—both in product and in people.

At PIMMS Group, the clean room reflects our ongoing commitment

to precision, performance, and continuous improvement.

We offer turnkey solutions that take your project from moulding to final product assembly, ensuring each component is expertly crafted and seamlessly integrated. With efficient logistics and supply chain management, we guarantee timely delivery and cost-effective solutions that keep your production running smoothly.

Our assembly and supply chain support includes

Turnkey solutions from moulding to final product assembly

Full-service support, delivering ready-to-market products.

Efficient logistics and supply management

Streamlined processes that ensure reliable, on-time delivery while optimizing costs.

With our end-to-end capabilities, you can trust that every detail is handled with precision, so you can focus on what matters most- growing your business.

Management ensures that our Quality Policy is communicated and understood by all personnel in the organization.

View our Quality Policy Statement and SABS Certificate of Registration.

A legal professional with a strategic mindset,

Veronique played a key role in shaping PIMMS Group while running her own law practice. Whilst co-leading Stanton Global with Stephen Stanley, Veronique drives marketing, HR, and governance initiatives across the group, bringing purpose, clarity, and compliance

to everything we do.

If you have an existing mould and you are unhappy with the moulded products, we invite you to consult with our engineering team. They can conduct a product material research study on your behalf at a reasonable fee to determine the requirements of your product, what the mechanical properties need to be, the weathering and UV stability needed, whether it’s an engineering application, whether it needs to be printed on, whether it needs to withstand chemical resistance and other considerations.

We highly recommend performing services on moulds (just like servicing your vehicle once a year). We can receive the mould at our premises and undertaking the following:-

Our clients refer to us as the “glue” that keeps their projects together and on track. Our developed insight into all necessary functions is integral to a clean development process. Our visual communication skills often become the “interpreters” between various departments of our corporate clients. Our qualified and professional team guides your product through the various checkpoints to ensure a successful outcome.

We’re able to provide all CAD and drawing information you require to secure the IP for your product. We can also refer you to several IP legal service providers.

All bells and whistles accounted for! From branding to instruction manuals to marketing material, we offer a highly specialised graphic design service to account for your launch needs.

This includes:

Using the latest modern software lets us generate computer animations and images for websites, print, and any other related marketing materials.

Usually, packaging is the first product experience the end-user usually has with your product. It is critical! Yet, so often this design function is left to the last-minute and treated half-heartedly. We design excellent, product- and concept-specific packaging ensuring a valuable, memorable and complete end-user experience.

For this, an exceptionally important part of the development process, we have our own 3D printing machines, rapid prototyping machines, and workshop facilities. Outside facilities are also at our disposal, both locally and in China. We base the choice of prototype method not on our facilities, but rather on which prototype solution is best suited to the required task.

Experiential Prototyping

Preliminary Prototyping

Final Prototyping

Our Product Design development cycle looks like this

It takes a great amount of experience to solve problems in innovative ways. Good thing we’ve got oodles of the stuff. We provide insight into multi-discipline solutions, guiding you to the most cost-effective and viable decisions at every juncture. This creates a wonderfully clear direction early on in the development process. As we go, we explore how parts are manufactured, how they fit and fasten to one another and how they interact with any of the standard components in the design.

At our IGC we sit with you over a brewed cup of coffee and brainstorm your idea.

Don’t be nervous, we’ll ask the important questions, draw sketches, strategise and assist with formulating a realistic budget.Don’t be nervous, we’ll ask the important questions, draw sketches, strategise and assist with formulating a realistic budget, and bring forward creative solutions to meet your requirements.

We offer product material options, manufacturing options and help you understand the project roadmap that will take your product from an idea to a tangible reality. We’ve got you!

Keeping your idea protected is paramount and we understand the need for confidentiality and trust. We love NDAs and are more than happy to sign one. In fact, we even have an NDA template if the dog ate yours.

Innovation distinguishes between a leader and a follower

Steve Jobs.